BJZX releases 3D animation illustrating IQF shrimp processing

2024-04-23 10:00BJZX released a 3D animation of its innovative IQF Shrimp Processing Line

With a focus on shrimp processing, BJZX released a 3D animation of its IQF Shrimp Processing Line that details features of the technology that allow it to achieve quality IQF shrimp while using minimal resources in terms of labor, energy and water consumption. The detailed and graphic representation of each part of the equipment shows how they work together to achieve a smooth process.

The IQF Shrimp Processing Line 3D video features a Bin Tipper and Wet Feed Bunker, Flow Control Infeed Belt, BJZX Cooker, Chiller and the IQF Freezer, which furthers the understanding of the line and the processes within.

The BJZX Shrimp Processing Line aims to provide:

l Labor saving and reduced hygiene risk

l 97.5% (+- 3%) installed capacity utilization

l Uniform infeed layer into the cooker

l Consistent shrimp color

l No shrimp clumping during freezing

Higher production yield with even cooking

The automated bulk infeed system requires only one person for its 4000 kg/and up capacity. The automated flow control system allows an even layer of shrimp to enter the BJZX Cooker, which contains three temperature zones to prevent protein loss and overcooking. Temperature change along each zone is less than 2°C, thus little energy is consumed in reheating the water. A greater volume of product is processed by the uniquely designed rainshower cooking system, which can penetrate a high layer of shrimp, providing 92%+ yield without the need to separately lay each piece of product on the belt. Furthermore, water consumption is 80-90% less than traditional methods as it is always filtered and recycled.

“The cooker design makes cooking time perfectly controlled. The water showers create the precise temperature control and by using water, shrimps are evenly cooked through conduction. This cooker can really control the temperature hitting the product.” ~ Marine Gold Products, Thailand

Achieving product quality through faster chilling & freezing

High quality IQF freezing is a two-step process; by cooling the product core with ice cold water in the BJZX Chiller and then freezing it in the BJZX IQF Freezer. The BJZX Chiller ensures quick chilling to the core to less than 5°C by spraying 1°C water, while meeting hygiene needs. No manpower is required in BJZX cooking and chilling systems which further brings down operational costs for increased profitability.

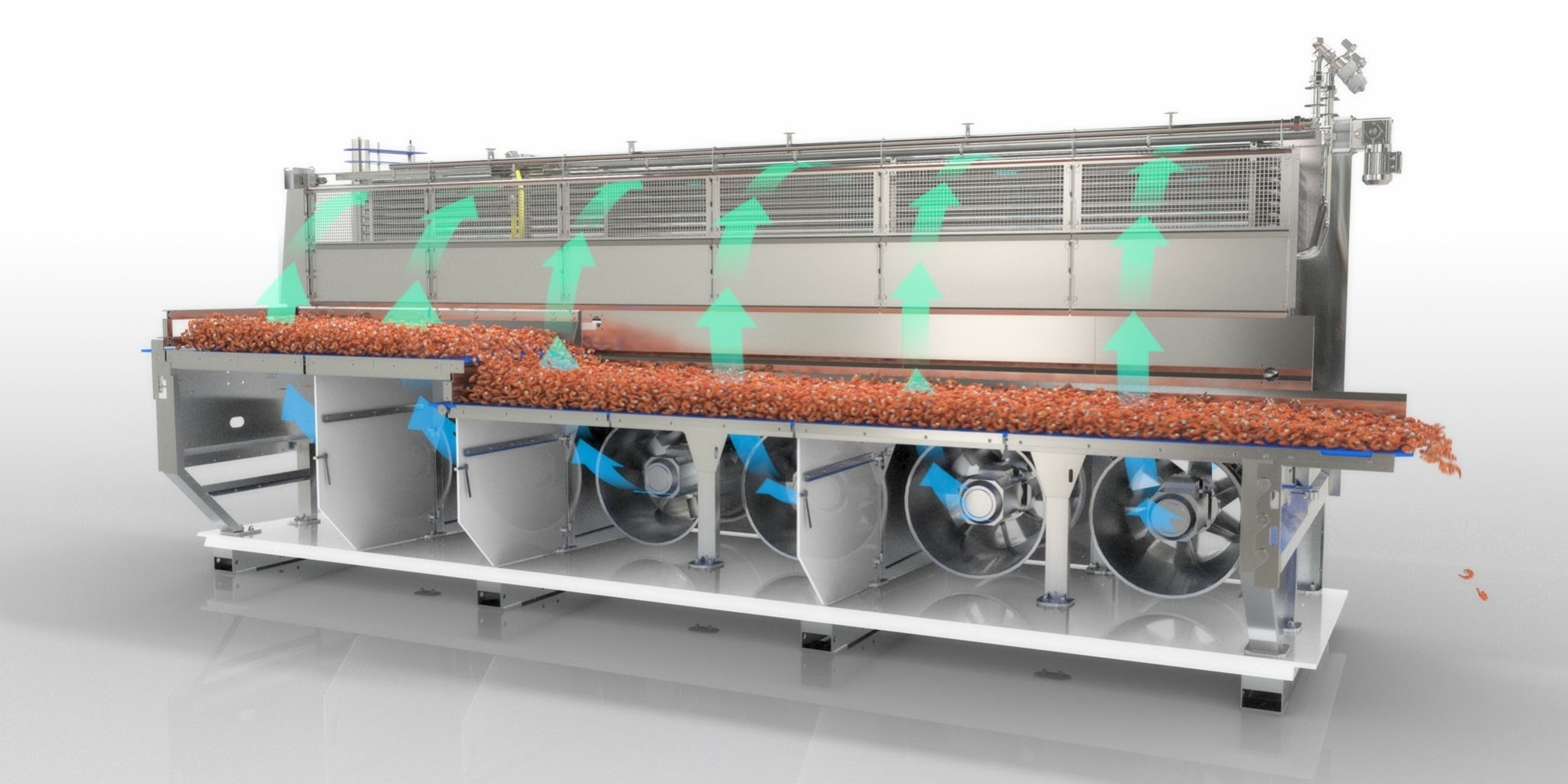

The BJZX IQF Freezer is versatile in that it allows a variety of shrimp to be processed. With the help of 3D visualization, concepts like fluidization through unique air-flow dynamics are made more concrete, which aim to provide faster chilling and higher energy efficiency. Processors can also opt for optional features in the IQF Freezer that include bedplate vibrator, waveplate, or a pulsator, to achieve unparalleled product separation. The IQF Freezer is also equipped with a coil Snow Removal System and an efficient foaming cleaning and rinsing system.

After freezing, the shrimp is uniformly glazed with multiple showers and separated through two points of motion in the glazer belt. Processors can opt for single, double or triple glazing options, as per customer’s preference. The shrimp is then moved to the glaze hardener, before being frozen in the second IQF Freezer.

Food safety through innovation & continuous improvement

Among the important features of the line are the easy-to-exchange bedplates with a puzzle connection. This allows for cleaning and sanitation outside the freezer while avoiding cross-contamination of different batches of products. Production can run for 20-22 hours while the cleaning process takes only 60-90 minutes.

The characteristics of BJZX IQF Shrimp Processing Line set it apart in the industry. A complete line solution from a single manufacturer can facilitate seamless project implementation, support and high capacity production. By achieving energy efficiency, labor saving, food safety and higher production yield, BJZX succeeds in ensuring profitability for shrimp processors around the globe.