Food vacuum pre cooling machine

Vacuum cooling uses negative pressure (vacuum pump) to make evaporation occur. The water in the product evaporates at low pressure, which cools the product.

- BJZX

- China

- 20 days

- 100 Sets

- Information

FOOD VACUUM PRE-COOLING MACHINE

FEATURES

Vacuum precooler is a volume-type cooling method, the overall cooling rate is fast, the cooling is uniform, and the impact of packaging and stacking is small, especially suitable for all kinds of cooked food preservation and precooling.

Vacuum precooler for prepared vegetables can be used as Deli fast food vacuum precooler,Central kitchen rapid precooling machine,Pasta vacuum precooling machine,Braised meat brine vacuum cooling machine and so on.

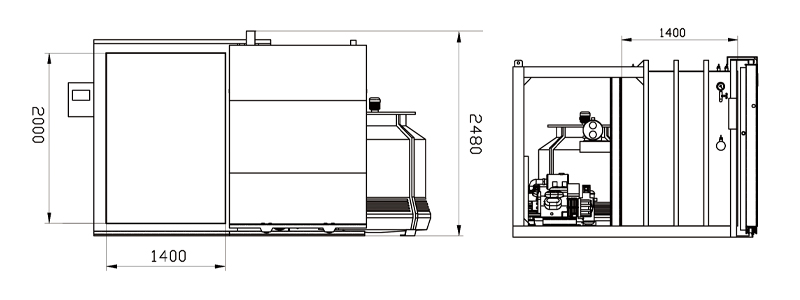

SPECIFICATION

| Model | BJ-MPQ |

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

Vacuum precooler is suitable for pre-cooling of various food, medicine, chemical and other items, and is widely used in the processing industry of vegetables, fruits, seafood and other food.

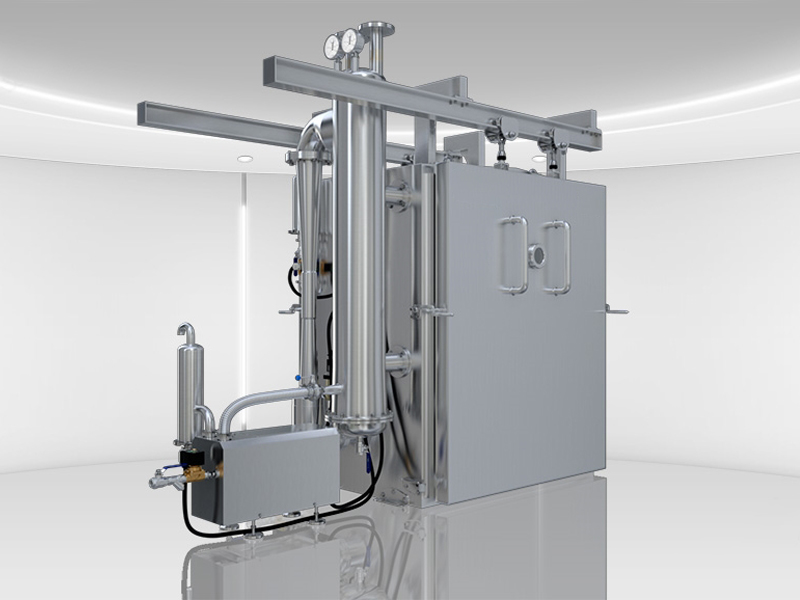

PRODUCT DETAILED

The basic principle of the vacuum cooling machine is to use the vacuum system to reduce the environmental pressure of the material to be cooled, so that the boiling point of the water in the material to be cooled is reduced and evaporated, so as to absorb the heat of the material to be cooled. The vacuum cooler can quickly and evenly remove the heat of cooked food, and can avoid the temperature zone of rapid bacterial reproduction compared with the traditional cold storage, thus significantly extending the freshness period and improving the quality of preservation.

PRODUCT DESCRIPTION

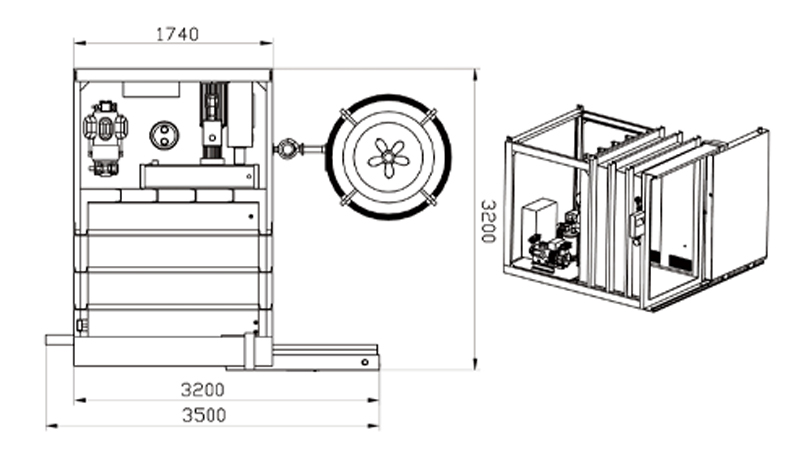

The main component of the vacuum cooling device The basic composition of the vacuum precooling device:

The vacuum treatment chamber, vacuum system, refrigeration system and control system are composed of four parts.

The inner material is determined by the nature of the cooling item, made of 304 stainless steel;

The outer side is welded with high-strength rectangular steel pipe and channel steel and sprayed with high-strength anti-rust material.

The vacuum system is the pumping system, which is composed of vacuum pumps and pipelines. After connecting the power supply and pipelines on site, the cooked food vacuum cooler realizes full automatic control through the PLC program control system.

The refrigeration system includes matching semi-enclosed screw or piston compressors, condensers, evaporators, as well as gas, oil, reservoir and refrigeration lines.

MACHINE CONSTRUCTION

Vacuum precooler for prepared vegetables&Deli fast food vacuum precooler&Central kitchen rapid pre cooling machine&Pasta vacuum precooling machine&Braised meat brine vacuum cooling machine&Vacuum precooler for prepared vegetables&Deli fast food vacuum precooler&Central kitchen rapid pre cooling machine&Pasta vacuum precooling machine&Braised meat brine vacuum cooling machine&Deli fast food vacuum precooler&Central kitchen rapid pre cooling machine&Pasta vacuum precooling machine

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!