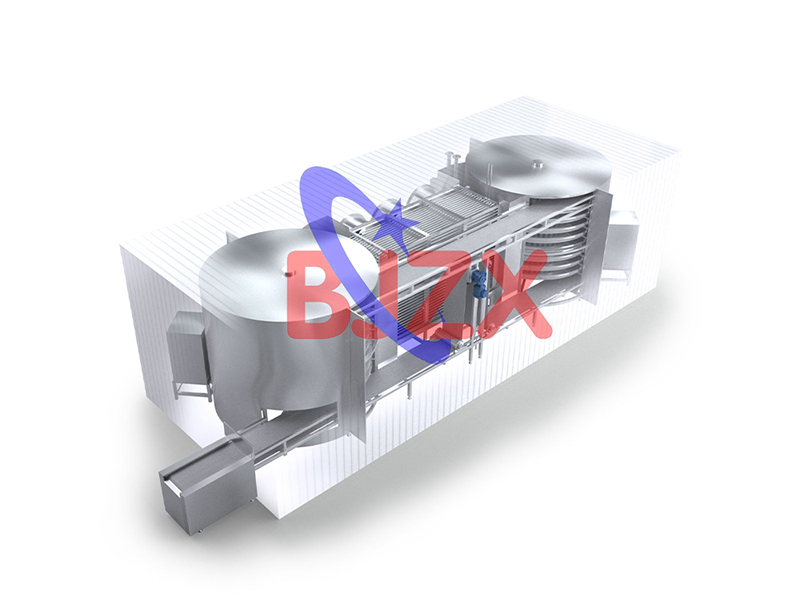

Double spiral freezing machine

BJ-SDX Double spiral quick freezer is a kind of energy-saving quick-freezing device with advanced technology, wide application, small area and large freezing capacity. It has been further perfected and improved on the basis of ordinary type. The use of modular or integral one time foam molding floor, so that the performance and structure of the equipment is more perfect, stability, insulation has been further improved and strengthened.

- BJZX

- China

- 20 days

- 10set

- Information

- Download

Double spiral quick freezer

FEATURES

Double spiral quick freezer can be used as pastry dairy frozen machine IQF, pickled meat double spiral IQF,seafood double spiral freezing machine,Double spiral dumpling freezing machine,and so on.

Double spiral quick freezer can be customized according to customer output requirements, to solve the problem of product freezing quantity, from the low feed, from the low discharge, can be connected with the customer's front and back processing production line on the ground, easy to use.

SPECIFICATION

| Model | Freezing capacity(kg/h) | Freeze time(min) | Installed power(kw) | Cold consumption(kw) | Overall dimensions L×W×H(m) | Transmission bandwidth(m) |

| BJ-SDX2-500 | 500 | 10~120 | 18.35 | 99 | 11.5×4.0×3.0 | 0.48 |

| BJ-SDX2-1000 | 1000 | 10~120 | 26.95 | 175 | 14.5×5.0×3.0 | 0.71 |

| BJ-SDX2-1500 | 1500 | 10~120 | 33.75 | 263 | 14.5×5.0×3.8 | 0.71 |

| BJ-SDX2-2000 | 2000 | 10~120 | 43.50 | 350 | 16.5×5.68×3.5 | 0.81 |

| BJ-SDX2-3000 | 3000 | 10~120 | 57.50 | 480 | 16.5×5.68×4.8 | 0.81 |

Note:

Feed temperature: ≤+15℃, discharge temperature: -18℃

Freezing temperature: -37℃±2℃

Cooling consumption: calculated according to condensation temperature +35℃, evaporation temperature -45℃

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

Pastry dairy frozen machine IQF

Pickled meat double spiral IQF

Seafood double spiral freezing machine

Double spiral dumpling freezing machine

Double spiral quick freezer application scope:

Prepared food, ice cream, pastry, aquatic products, meat and poultry, fried food, small packaged food, etc.

PRODUCT DETAILED

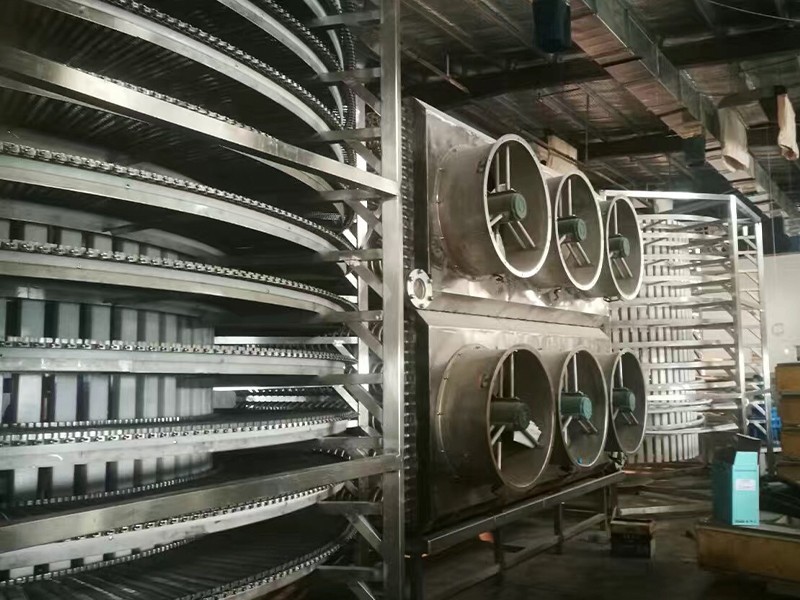

The tunnel structure design of double spiral dumpling freezing machine is more optimized, the floor area is smaller, the quick-freezing efficiency is higher, and the freezing chain length is longer, which increases the freezing contact time, increases the freezing quality and the output per unit time.

PRODUCT DESCRIPTION

Compared with the general tunnel type, the installed capacity is reduced by 35%, the cooling capacity of the whole machine is less, and the economy of less freezing is improved.

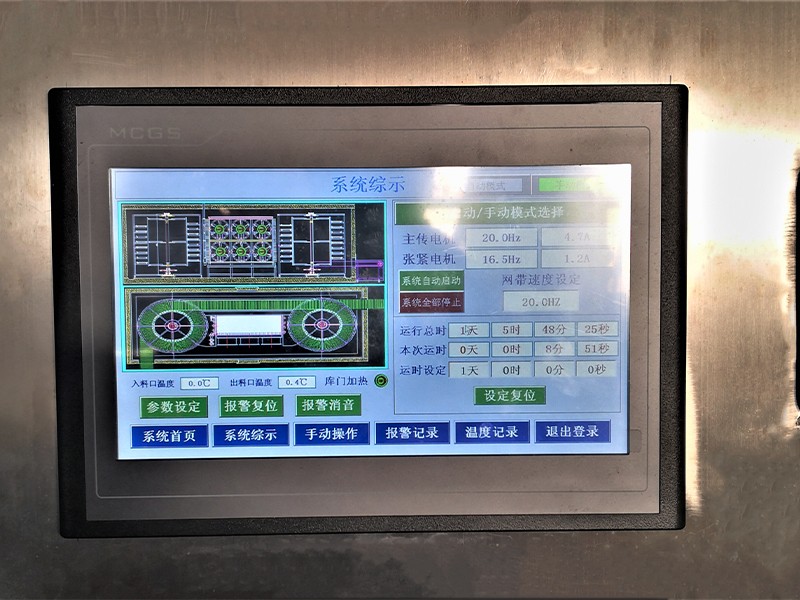

The advanced computer touch control system is adopted, the touch screen adopts domestic Kunlun open state products, the PLC adopts Japanese Omron products, the frequency converter, electronic proximity switch and electrical components adopt domestic well-known brands, and the whole control panel is operated without buttons, which is convenient and concise.

PRODUCT OUTCOME CASE

Pastry dairy frozen machine IQF

Pickled meat double spiral IQF

Pastry dairy frozen machine IQF —— located in Tieling City, Liaoning Province, China

Pickled meat double spiral IQF - located in Shijiazhuang, Hebei Province, China

MACHINE CONSTRUCTION

Pastry dairy frozen machine IQF&Pickled meat double spiral IQF&Seafood double spiral freezing machine&Double spiral dumpling freezing machine&seafood double spiral freezing machine

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!