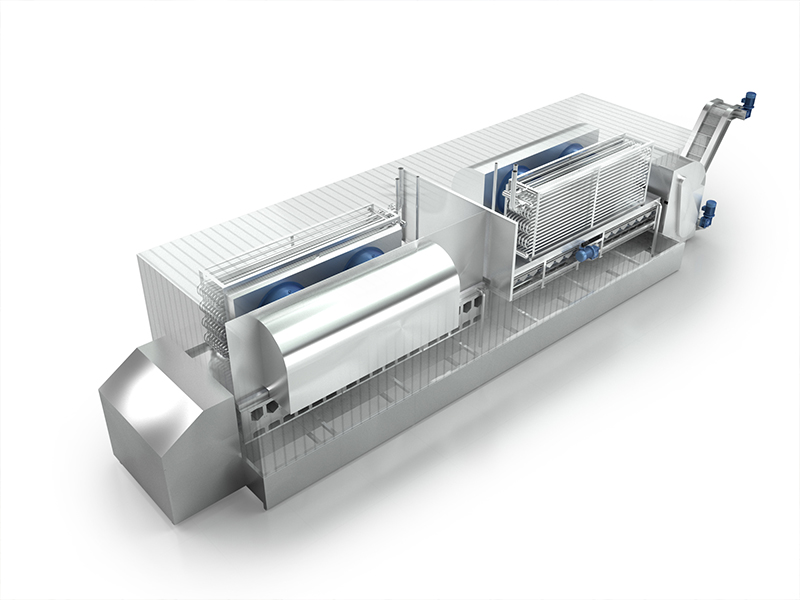

Steel Belt Freezing Machine

BJ-SB IQF Tunnel Freezer Customized Quick Freezing is a rapid freezing device with high freezing capacity and wide application range. It is widely applicable to the rapid freezing of various aquatic products such as fish fillets, shrimp and shellfish, segmented meat and poultry and prepared food.

- BJZX

- China

- 20 days

- 100set

- Information

- Download

IQF Tunnel Freezer Customized Quick Freezing

FEATURES

Steel belt freezing machine can be used as IQF tunnel freezer customized quick freezing,IQF Tunnel frozen fish poultry meat, stainless steel belt IQF tunnel freezer seafood, beef and mutton plate quick-freezing machine, impact steel belt quick-freezing machine,etc.

SPECIFICATION

| Model | Freezing capacity(kg/h) | Freeze time(min) | Installed power(kw) | Cold consumption(kw) | Overall dimensions L×W×H(m) | Transmission bandwidth(m) |

| BJ-SB1-150 | 150 | 6~60 | 9.55 | 26.25 | 8.5×2.48×2.6 | 1.22 |

| BJ-SB1-200 | 200 | 6~60 | 12.75 | 35.00 | 10.5×2.48×2.6 | 1.22 |

| BJ-SB1-250 | 250 | 6~60 | 18.35 | 43.75 | 12.5×2.48×2.6 | 1.22 |

| BJ-SB1-300 | 300 | 6~60 | 27.15 | 52.50 | 14.5×2.48×2.6 | 1.22 |

| BJ-SB1-400 | 400 | 6~60 | 37.50 | 72.00 | 18.5×2.48×2.6 | 1.22 |

| BJ-SB1-500 | 500 | 6~60 | 50.20 | 99.00 | 22.5×2.48×2.6 | 1.22 |

| BJ-SB2-500 | 500 | 6~60 | 38.20 | 99.00 | 11.5×4.25×2.6 | 2×1.00 |

| BJ-SB2-1000 | 1000 | 6~60 | 78.00 | 175.00 | 20.5×4.25×2.6 | 2×1.00 |

Note:

Feed temperature: ≤+15℃, discharge temperature: -18℃

Freezing temperature: -37℃±2℃

Cooling consumption: calculated according to condensation temperature +35℃, evaporation temperature -45℃

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

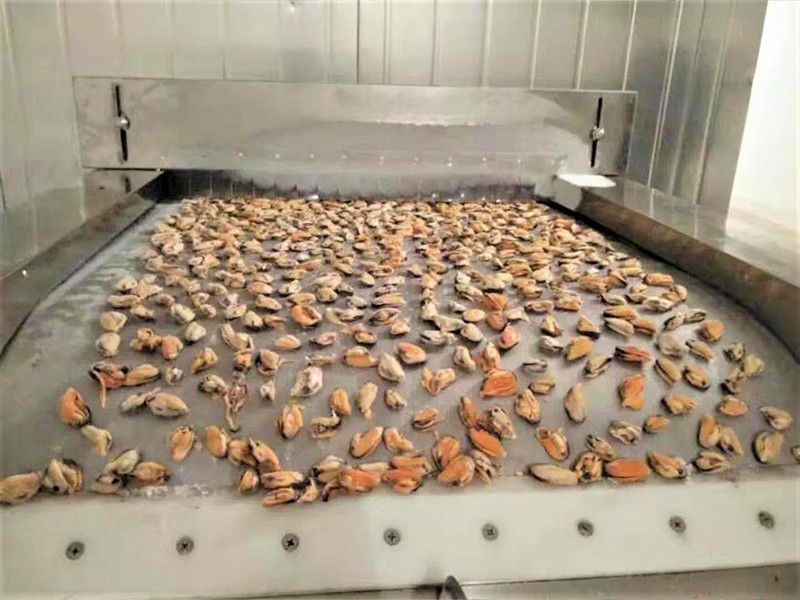

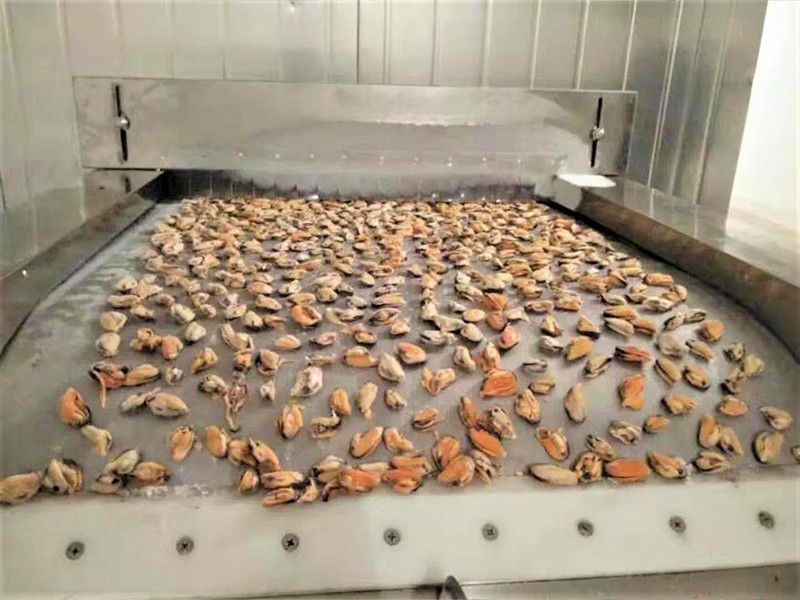

The impact steel belt quick-freezing machine is mainly for the quick freezing of flat food, mainly used in the aquatic industry, naked frozen fish fillet scallops, shrimp, various fish fillets, fish segments, hamburger patties, squid.

Beef and mutton plate quick-freezing machine is used for fast freezing of fried cakes, meat and other products that do not need to be platted.

PRODUCT DETAILED

The user of the impact steel belt quick-freezing machine does not have to bear the cost of the floor structure. (that is, the workshop floor)

PRODUCT DESCRIPTION

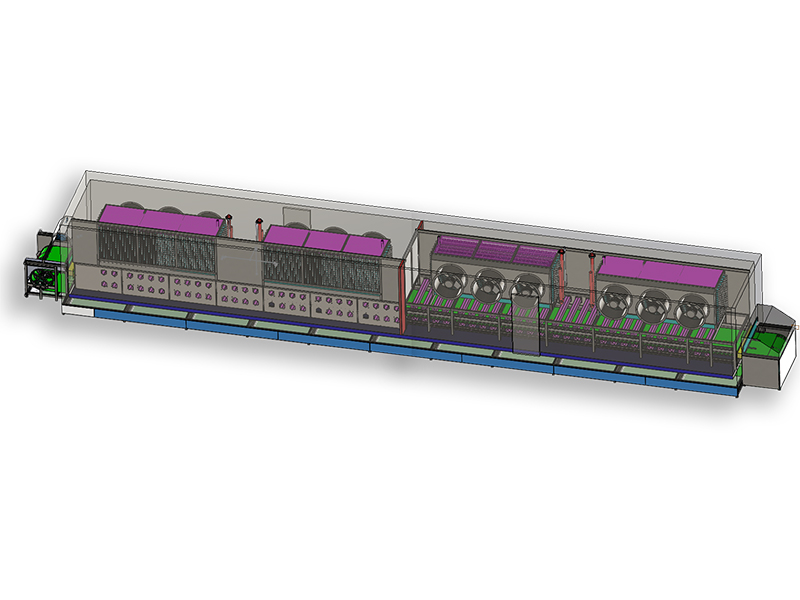

All stainless steel structure, the warehouse body adopts double-sided stainless steel polyurethane foam insulation board, with a thickness of 125mm, and all rust proof alumi- num evaporator, which has fast cooling speed and saves energy.

The mechanical transmission adopts full frequency conversion stepless speed regulation, with stable operation and convenient operation and maintenance.

IQF Tunnel frozen fish poultry meat,fully enclosed air duct, unique air distribution, all sides of food can be surrounded by air flow, with fast freezing speed and uniform freezing depth per unit time.

PRODUCT OUTCOME CASE

IQF tunnel freezer fish poultry meat

Stainless steel belt IQF tunnel freezer seafood

Beef and mutton plate quick-freezing machine

IQF tunnel freezer fish poultry meat

Stainless steel belt IQF tunnel freezer seafood

Beef and mutton plate quick-freezing machine

IQF tunnel frozen fish poultry meat—— exported to North Korea

Stainless Steel Belt IQF Tunnel Freezer Seafood —— exported to Korea

Beef and mutton plate quick-freezing machine —— located in Yanji, Jilin Province, China

MACHINE CONSTRUCTION

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!