Fluidized Quick-freezing Machine

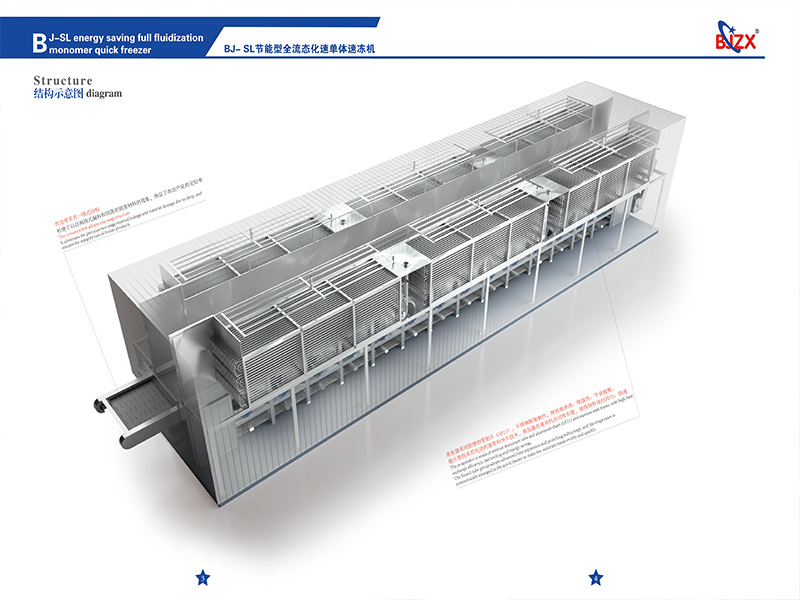

BJ-SL energy-saving full-fluidized mono quick-freezing machine is an improved quick-freezing machine developed on the basis of the ordinary full-fluidized quick-freezing machine. It is the patented product of our company (patent number :ZL200320105027.4), which has the characteristics of small floor area, large output, energy saving, beautiful appearance and so on. It is a product with advanced performance.

- BJZX

- China

- 20 days

- 100 set

- Information

- Download

IQF FLUIDIZED BELT TUNNEL FREEZER

FEATURES

Fluidized quick-freezing machine can be used as vegetable and fruit freezing machine, corn kernel food freezing machine,potato chip frozen machine IQF, IQF fluidized belt tunnel Freezer, meat seafood frozen machine IQF,etc.

Unique design structure of fluidized quick-freezing machine, convenient cleaning

High efficiency, energy saving, stable performance

High quality frozen products

Easy installation, easy maintenance, simple operation

SPECIFICATION

| Model | Freezing capacity(kg/h) | Freeze time(min) | Installed power(kw) | Cold consumption(kw) | Overall dimensions L×W×H(m) | Transmission bandwidth(m) |

| BJ-SL4-500 | 500 | 6~60 | 31.85 | 99 | 8.25×3.67×3.5 | 1.30 |

| BJ-SL4-1000 | 1000 | 6~60 | 48.15 | 160 | 10.25×3.67×3.5 | 1.30 |

| BJ-SL4-1500 | 1500 | 6~60 | 64.40 | 240 | 12.25×3.67×3.5 | 1.30 |

| BJ-SL4-2000 | 2000 | 6~60 | 81.75 | 320 | 14.25×3.67×3.5 | 1.30 |

| BJ-SL4-2500 | 2500 | 6~60 | 96.75 | 400 | 16.25×3.67×3.5 | 1.30 |

| BJ-SL4-3000 | 3000 | 6~60 | 111.75 | 480 | 18.25×3.67×3.5 | 1.30 |

| BJ-SL4-3500 | 3500 | 6~60 | 126.75 | 560 | 20.25×3.67×3.5 | 1.30 |

| BJ-SL4-4000 | 4000 | 6~60 | 157.70 | 640 | 24.25×3.67×3.5 | 1.30 |

| BJ-SL4-4500 | 4500 | 6~60 | 174.30 | 720 | 26.25×3.67×3.5 | 1.30 |

| BJ-SL4-5000 | 5000 | 6~60 | 189.30 | 800 | 28.25×3.67×3.5 | 1.30 |

| BJ-SL4-5500 | 5500 | 6~60 | 204.30 | 880 | 30.25×3.67×3.5 | 1.30 |

| BJ-SL4-6000 | 6000 | 6~60 | 206.30 | 960 | 32.25×3.67×3.5 | 1.30 |

Note:

Feed temperature: ≤+15℃, discharge temperature: -18℃

Freezing temperature: -37℃±2℃

Cooling consumption: calculated according to condensation temperature +35℃, evaporation temperature -45℃

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

Vegetable and fruit freezing machine

Corn kernel food freezing machine

Potato chip frozen machine IQF

Meat seafood frozen machine IQF

IQF fluidized belt tunnel freezer is suitable for rapid freezing of granular, block, cylindrical, T-shaped, strip, small food, fruit and vegetable monomer.

Vegetable and fruit freezing machine can be used to freeze sliced or diced vegetables, fruits and berries.

Corn kernel food freezing machine can be used to freeze edamame, corn and other small grains, small pieces of food.

Potato chip frozen machine IQF can be used to freeze potato chips, French fries, potato chips and other foods.

Meat seafood frozen machine IQF can be used to freeze meat, poultry, seafood (such as small fish or shrimp), small pieces of dairy or cooked food.

PRODUCT DETAILED

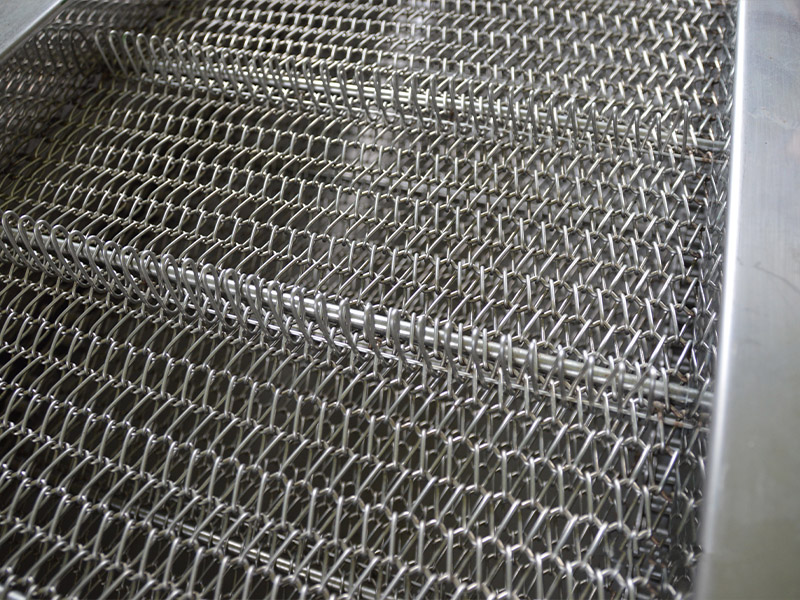

IQF fluidized belt tunnel freezer with the unique design of both sides of the conveyor belt with baffle plate, to eliminate the usual product leakage phenomenon.

PRODUCT DESCRIPTION

Water cleaning device is adopted at the feed end to shorten the equipment cleaning and frost flushing time.

The feeding and discharging end adopts double scraper device to make the conveyor belt clean and clean.

There are special maintenance and cleaning channels inside, without sanitary dead corners.

IQF fluidized belt tunnel freezer does not require pre-cooling equipment, and has its own pre-cooling, surface freezing and deep freezing functions.

The inlet end adopts a wind guide device to guide the wind direction, reduce the loss of cold quantity, and no running cold phenomenon.

The external fan motor does not consume the cold capacity of the quick-freezing machine, and the full frequency speed regulation reduces the cold consumption of the device by nearly 30% compared with other quick-freezing machines, saving energy and improving the cooling speed.

High pressure double suction centrifugal fan, one is equivalent to two ordinary centrifugal fans, the full pressure of the fan is 1300Pa, the air volume is 21000m3 /h, and the material is stainless steel structure.

The fan and conveyor belt adopt full frequency conversion stepless speed change, so that the materials can be transported forward with the suspended waves of low-temperature cold air in the unique air duct. In addition, the device is equipped with kneading pulse vibration mechanism to ensure that the product fully freezes, the monomer rate is 100%, the equipment has a wide range of frozen products, and the freezing time is adjustable.

The external fan motor can repair the equipment without affecting the normal production.

Common floor structure, integrated or modular assembly and delivery, and common workshop floor can save costs.

After the equipment is in place, users only need to connect the power supply, cold source and frost flushing water to produce, so as to shorten the equipment installation cycle.

The electric control cabinet panel LCD displays the freezing temperature and speed regulation range, which is convenient and simple to operate.

PRODUCT OUTCOME CASE

Vegetable and fruit freezing machine

CORN KERNEL FOOD FREEZING MACHINE

Vegetable and fruit freezing machine —— located in Zhanjiang, Guangdong Province, China

Used for frozen pineapple cubes and other fruits.

Corn kernel food freezing machine -- located in Fushun, Liaoning Province, China

For quick-frozen shiitake mushrooms.

MACHINE CONSTRUCTION

Vegetable and fruit freezing machine\Corn kernel food freezing machine\Potato chip frozen machine IQF\IQF Fluidized Belt Tunnel Freezer\meat seafood frozen machine IQF\Potato chip frozen machine IQF\Potato chip frozen machine IQF\Potato chip frozen machine IQF\Potato chip frozen machine IQF\Meat seafood frozen machine IQF\Meat seafood frozen machine IQF\Meat seafood frozen machine IQF\Corn kernel food freezing machine\IQF Fluidized Belt Tunnel Freezer

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!