Net Belt Type Freezing Machine

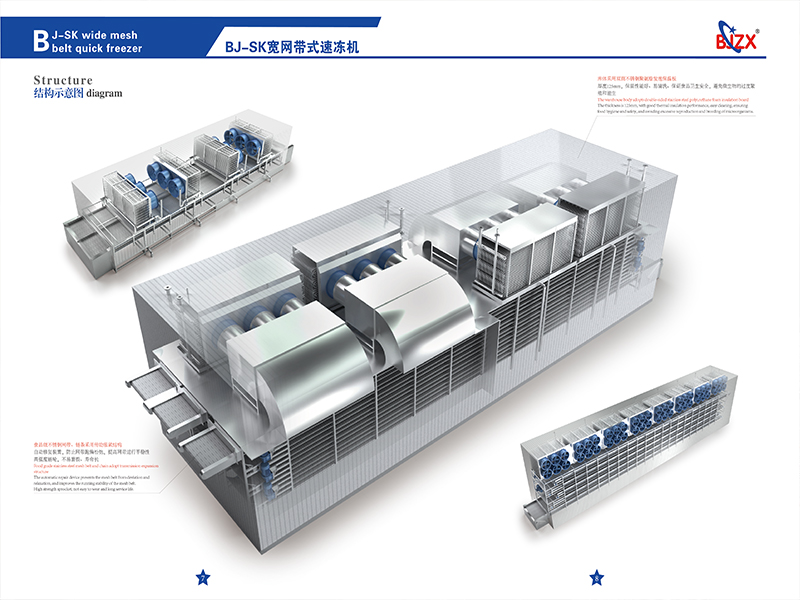

BJ-SK mesh belt freezer integrates the advantages of domestic and foreign counterparts and introduces HACCP health and safety concept. It is all stainless-steel structure, convenient for cleaning, maintenance and management, all rust proof aluminum evaporator, fast cooling speed, energy saving, beautiful appearance, advanced performance and easy operation. It is a quick freezer with high freezing capacity and wide application range.

- BJZX

- China

- 20 days

- 10set

- Information

- Download

Crab stick frozen food tunnel freezer IQF

FEATURES

Net belt type freezing machine can be used as vegetable mesh belt quick freezer, dumpling tunnel type frozen machine, squid ring freezing equipment IQF, fruit tunnel quick freezing machine, crab stick frozen food tunnel freezer IQF and so on.

It has the advantages of simple structure, easy operation and long service life.

SPECIFICATION

BJ-SK1 Main technical parameters of mesh belt quick freezer

| Model | Freezing capacity(kg/h) | Freeze time(min) | Installed power(kw) | Cold consumption(kw) | Overall dimensions L×W×H(m) | Transmission bandwidth(m) |

| BJ-SK1-50 | 50 | 6~60 | 6.55 | 8.75 | 8.0×1.75×2.00 | 0.90 |

| BJ-SK1-100 | 100 | 6~60 | 6.75 | 18 | 9.5×2.05×2.35 | 1.50 |

| BJ-SK1-150 | 150 | 6~60 | 9.35 | 26.25 | 11.5×2.20×2.35 | 1.75 |

| BJ-SK1-200 | 200 | 6~60 | 9.55 | 35 | 13.5×2.20×2.35 | 1.75 |

| BJ-SK1-300 | 300 | 6~60 | 12.75 | 55 | 17.5×2.20×2.35 | 1.75 |

| BJ-SK1-400 | 400 | 6~60 | 13.50 | 72 | 17.5×2.65×2.6 | 2.15 |

| BJ-SK1-500 | 500 | 6~60 | 19.10 | 90 | 18.5×2.65×2.6 | 2.35 |

BJ-SK2 Main technical parameters of mesh belt quick freezer

| Model | Freezing capacity(kg/h) | Freeze time(min) | Installed power(kw) | Cold consumption(kw) | Overall dimensions L×W×H(m) | Transmission bandwidth(m) |

| BJ-SK2-500 | 500 | 10~100 | 12.75 | 99 | 11.5×3.00×2.6 | 2.5 |

| BJ-SK2-1000 | 1100 | 10~100 | 26.20 | 175 | 16.5×3.55×2.6 | 3.0 |

| BJ-SK2-1500 | 1500 | 10~100 | 39.00 | 265 | 20.5×4.05×2.6 | 3.5 |

BJ-SK3 Main technical parameters of mesh belt quick freezer

| Model | Freezing capacity(kg/h) | Freeze time(min) | Installed power(kw) | Cold consumption(kw) | Overall dimensions L×W×H(m) | Transmission bandwidth(m) |

| BJ-SK3-150 | 150 | 6~60 | 9.55 | 26.25 | 9.5×2.48×2.60 | 1.36 |

| BJ-SK3-200 | 200 | 6~60 | 13.95 | 35.00 | 11.8×2.48×2.60 | 1.36 |

| BJ-SK3-250 | 250 | 6~60 | 18.35 | 43.75 | 13.5×2.48×2.60 | 1.36 |

| BJ-SK3-300 | 300 | 6~60 | 27.90 | 52.50 | 17.0×2.48×2.60 | 1.36 |

| BJ-SK3-400 | 400 | 6~60 | 28.60 | 72.60 | 17.0×2.60×2.60 | 1.76 |

| BJ-SK3-500 | 500 | 6~60 | 37.40 | 90.00 | 20.5×2.60×2.60 | 1.76 |

Note:

Feed temperature: ≤+15℃, discharge temperature: -18℃

Freezing temperature: -37℃±2℃

Cooling consumption: calculated according to condensation temperature +35℃, evaporation temperature -45℃

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

Dumpling tunnel type frozen machine

Squid ring freezing equipment IQF

Fruit tunnel quick freezing machine

Crab stick frozen food tunnel freezer IQF

vegetable mesh belt quick freezer, dumpling tunnel type frozen machine, squid ring freezing equipment IQF, fruit tunnel quick freezing machine used in all kinds of vegetables, fruits, aquatic products, poultry, meat, conditioning, pastry, ice cream frozen processing, all stainless steel structure, to ensure food safety and health. The automatic anti-deviation system can automatically adjust the abnormal operation in the network belt, the air supply system has multiple changes and uniform air distribution, and the freezing speed is fast and the frozen product quality is high.

PRODUCT DETAILED

Vegetable mesh belt quick freezer adopts high strength SUS304 plate to carry frozen products, the surface is flat, the conveyor belt width can be selected according to customer requirements, the freezing capacity is strong, the operation is convenient, to ensure cleanliness and health, easy maintenance.

PRODUCT DESCRIPTION

Reasonable access door and access are provided to facilitate maintenance

and internal cleaning.

The unique evaporator flushing and cleaning design can clean quickly and

effectively.

The mechanical transmission adopts full frequency conversion stepless

speed regulation, with stable operation and convenient operation and

maintenance.

Fully closed air duct and unique air flow organization, so that all sides of the food flow around the air, freezing speed is fast, freezing depth per unit time is uniform, heat transfer efficiency is more than 30% higher than the traditional form

The user does not have to bear the cost of the floor structure (i.e. the workshop floor)

The user does not have to bear the cost of the floor structure (i.e. the workshop floor)The stainless steel square pipe adopts 50x50x2.0mm specification, the internal windshield adopts 2mm stainless steel plate, and the convection air duct adopts 1.5mm stainless steel plate.

The running speed can be adjusted by frequency conversion, and the freezing time can be adjusted continuously to adapt to the processing of various frozen products

PRODUCT OUTCOME CASE

Crab stick frozen food tunnel freezer IQF

Dumpling tunnel type frozen machine

Crab stick frozen food tunnel freezer IQF —— located in Shijiazhuang, China

Dumpling tunnel type frozen machine —— located in Tieling City, China

MACHINE CONSTRUCTION

vegetable mesh belt quick freezer, dumpling tunnel type frozen machine, squid ring freezing equipment IQF, fruit tunnel quick freezing machine&vegetable mesh belt quick freezer&vegetable mesh belt quick freezer&Squid ring freezing equipment IQF&Squid ring freezing equipment IQF&Fruit tunnel quick freezing machine&Fruit tunnel quick freezing machine

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!