Basket washing machine

Frame washing machine using high pressure warm water cleaning, you can also choose to add cleaning solvents according to the different degrees of dirty baskets, using the impact force to separate the dirt from the box, after cleaning can be equipped with air drying machine, the surface water quickly dry, immediately reused.

- BJZX

- China

- 20 days

- 100 Sets

- Information

BASKET WASHING MACHINE

FEATURES

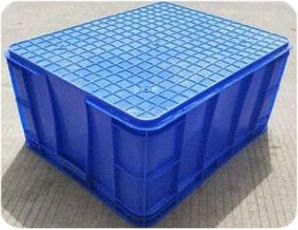

Turnover basket washing machine, stainless steel hot alkali water washing basket machine is used to clean the turnover basket used in each plant, that is, the food basket, which is dirty when repeatedly used, but manual cleaning is more laborious, but not cleaning can not meet the new health requirements standards, but also easy to breed bacteria, affecting the production quality of products. The output is also relatively small, in order to achieve automatic cleaning baskets, our company produces automatic high pressure spray cleaning machine, fast and efficient cleaning material frame.

Turnover basket cleaning machine can be used as high pressure spray type basket washer,Egg basket mud cleaning machine,Plastic basket box tray cleaning machine,Crawfish turnover basket cleaning equipment and so on.

SPECIFICATION

| Model | BJ-KQ |

| Dimensions | 6200×1500×1500 mm |

| Power | 7.35 kw |

Products can be customized, more model parameters please contact me

RANGE OF CONFIGURATION

Basket washing machine has a wide range of applications, which is used for turnover industry turnover industry turnover basket cleaning machine, food industry food box cleaning machine, and can also be used to wash very dirty chocolate trays.

PRODUCT DETAILED

The turnover basket to be cleaned is input into the spray basket washing machine by the stainless steel chain, and the process of heating old alkali water → high pressure hot water → normal temperature tap water → sterilizing water → normal temperature air knife to remove water is followed. Stainless steel hot alkali water washing basket machine Spray washing basket machine pipeline adopts snap installation form, easy to clean the pipeline and reliable operation, using stainless steel conveyor chain and stainless steel nozzle, long service life.

PRODUCT DESCRIPTION

The equipment is divided into 2 sections of cleaning and 3 sections of cleaning, generally each section is 2 meters, that is, 4 meters and 6 meters

The speed is variable frequency

The speed regulating motor can adjust the speed of cleaning, and the running speed of the equipment can be adjusted according to the degree of dirt of the box

The more dirty frame can be adjusted slowly so that the cleaning will be more clean

Like vegetable turnover baskets are cleaner and less oily

Stainless steel hot alkali water washing machine can quickly wash and save water, meet the requirements of different customer production volumes of turnover box cleaning, reduce labor, improve production efficiency, long service life.

Our factory mainly produces a variety of basket cleaning machine, saving labor, turnover basket cleaning machine line cleaning efficiency is high, the whole machine is made of 304 stainless steel material, model and configuration can be customized according to customer requirements, with high production efficiency, good cleaning effect, low energy consumption, turnover basket cleaning machine line long service life and other characteristics.

The equipment mainly adopts stainless steel hot water cleaning pump, which can replace the traditional manual cleaning operation

MACHINE CONSTRUCTION

Turnover basket cleaning machine&high pressure spray type basket washer&Egg basket mud cleaning machine&Plastic basket box tray cleaning machine&Crawfish turnover basket cleaning equipment&high pressure spray type basket washer&Egg basket mud cleaning machine&Plastic basket box tray cleaning machine&Crawfish turnover basket cleaning equipment&high pressure spray type basket washer&Egg basket mud cleaning machine&Plastic basket box tray cleaning machine&Crawfish turnover basket cleaning equipment&Egg basket mud cleaning machine

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!