Fresh Ginger Cleaning Machine

Fresh ginger cleaning machine according to the need to design two, one is used for fresh ginger cleaning and peeling, the other is dedicated to ginger cleaning.

- BJZX

- China

- 20 days

- 100 Sets

- Information

FRESH GINGER CLEANING MACHINE

FEATURES

Fresh ginger cleaning and peeling machine adopts food-grade brush for conveying and cleaning, the use of rotary brush with high pressure spray, good cleaning effect, can thoroughly clean the stains on the surface of fresh ginger, with large effective cleaning, high efficiency, water saving, continuous cleaning, simple operation, long service life and so on.

Fresh ginger cleaning machine through bubbling, surfing and spraying three cleaning methods, so that fruits and vegetables cleaning more clean, with water, electricity, time saving, clean health, no damage to the product and so on.

SPECIFICATION

| Model | BJ-JQ |

| Dimensions | 8500×1300×1750 mm |

| Motor power | 20.35 kw |

| Operating speed | frequency conversion control |

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

Before the carrots are washed

After the carrots are peeled

Before the ginger is washed

After the ginger is washed

Fresh ginger cleaning (peeling) machine is widely used in ginger, carrots, potatoes, sweet potatoes, kiwifruit and other round oval fruits and vegetables root crop cleaning, peeling.

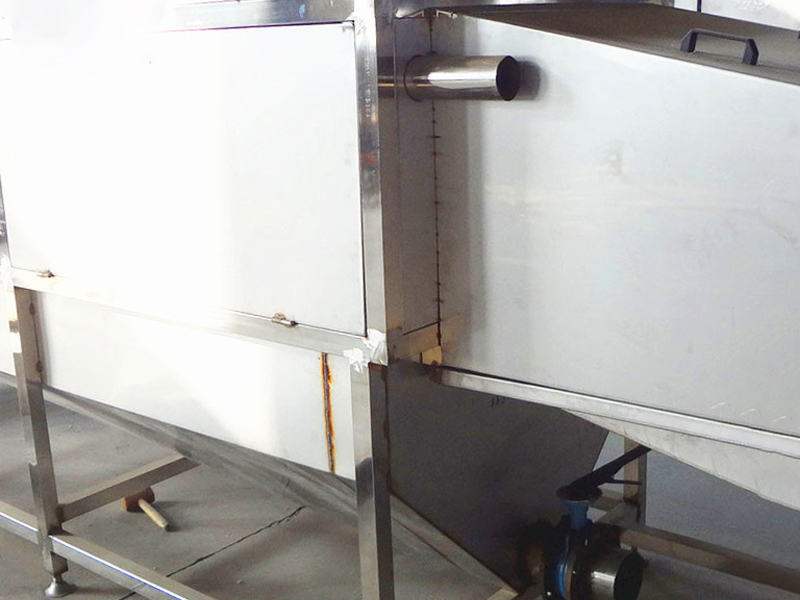

PRODUCT DETAILED

Ginger (or other fruits and vegetables) by artificial (or hoist) into the sink, under the action of high pressure water flow and strong bubbles, tumbling, cleaning, transfer. The eluted sediment from the surface of the material sinks into the bottom isolation bin, which will not cause re-pollution due to overturning and backflow. After washing the fruit and vegetable water, it is washed by spray and sent to the next process. With its own water circulation system, the water consumption is low. The process of cleaning, removing foreign matter, sterilization and cooling can be carried out continuously. The cleanliness of the cleaned material is more than three times higher than that of manual conventional washing.

PRODUCT DESCRIPTION

Spray cleaning device

Nozzle direction can be adjusted, no dead Angle cleaning cleaner, saving time and effort.

Nylon roller

The wool roller made of high quality nylon silk has strong cleaning ability of soft wool, good peeling effect of hard wool, and different functions of soft and hard effect.

Stainless steel body

The whole machine is made of 304 stainless steel, corrosion resistant, in line with national food hygiene standards, easy to clean, more durable, not easy to deform.

Power cleaning

Brush, spray cleaning, powerful cleaning function. High-pressure spray in the operation of the fan water, thoroughly remove mud, dust and other impurities.

Customized service

The material of the hair cone is treated by special process. According to different materials can choose soft hair, hard hair, straight hair, wave hair, sand roller, to achieve cleaning, peeling, cleaning, polishing and other effects. Customized according to customer requirements.

MSCHINE CONSTRUCTION

Fresh ginger mud cleaning machine&Large ginger automatic cleaning machine&Ginger bubble cleaner&Stainless steel ginger cleaning machine&Ginger peeling machine&Fresh ginger mud cleaning machine&Large ginger automatic cleaning machine&Ginger bubble cleaner&Stainless steel ginger cleaning machine&Ginger peeling machine&Fresh ginger mud cleaning machine&Large ginger automatic cleaning machine&Ginger bubble cleaner&Stainless steel ginger cleaning machine&Ginger peeling machine&Fresh ginger mud cleaning machine&Large ginger automatic cleaning machine&Ginger bubble cleaner&Stainless steel ginger cleaning machine&Ginger peeling machine&Fresh ginger mud cleaning machine&Large ginger automatic cleaning machine&Ginger bubble cleaner&Stainless steel ginger cleaning machine&Ginger peeling machine&Ginger bubble cleaner&Ginger bubble cleaner&Ginger bubble cleaner&Ginger peeling machine&Ginger peeling machine&Ginger peeling machine

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!