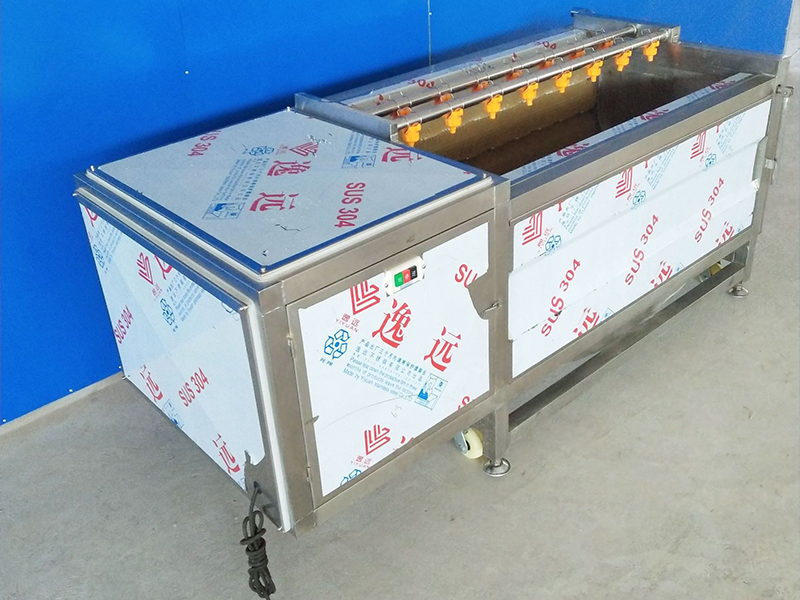

Shell Cleaning Machine

The shell cleaner is designed for the seafood processing industry. It pushes hard shell seafood such as oysters through a brush roller and brushes away the sand attached to the shell with friction.

- BJZX

- China

- 20 days

- 100 Sets

- Information

SHELL CLEANING MACHINE

FEATURES

The shell cleaning machine as a whole is made of high quality SUS304 stainless steel, the products meet the national food industry standards, the use of brush and spray technology, can maximize the cleaning of materials, cleaning speed using frequency converter control, cleaning speed can be freely adjusted, the waste collection area below has enough space for workers to remove waste, The new filter can completely separate the waste residue from the waste water. The waste residue is easily scraped away above the filter screen, and the wastewater is automatically discharged below the filter screen.

Shell roller cleaning machine can be used as Large shell conch cleaning machine,Oyster abalone puree cleaner,Automatic clam cleaning machine,Seafood decontamination cleaning machine and so on.

SPECIFICATION

| Model | BJ-BQ | BJ-BQ |

| Dimensions | 2450×850×820 mm | 2745×970×1235 mm |

| Wool roller | 9 pieces | 50 pieces |

| Motor power | 2.2 kw | 1.5 kw |

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

Clam

Chinese clam

Fresh oyster

Scallop

Shell cleaning machine is suitable for cleaning clams, scallops, fish, shellfish and other seafood, its structure is simple and practical, easy to use and disassemble.

PRODUCT DETAILED

When the seashell is put into the machine, the brush roller rotates to brush the seashell, and the seashell continues to turn, while the drain pipe continues to spray water to wash away the sediment on the oyster until it is washed, so that the material is discharged along the direction of the hair roller rotation.

PRODUCT DESCRIPTION

Compact structure and convenient operation

The whole machine is made of 304 stainless steel material, durable, no rust, no corrosion, with cleaning clean height, energy saving, water saving, stable and reliable equipment.

Large cleaning capacity, high efficiency, low energy consumption

Special discharge port design, fast discharge speed, no damage to the material, with auxiliary equipment into a processing line, depending on the cleaning degree of the material, can be cleaned separately, and then make the mesh belt transfer.

Nylon silk roller brush

Equipment brush roller scrubs the surface of the material, complete cleaning, polishing, peeling treatment, with wear-resistant, non-anti-hair, easy to clean the advantages.

Unique design, can be configured on demand

The top can be equipped with spray device, with good cleaning or peeling effect.

A dewatering tray and water outlet can also be installed at the bottom of the brush to prevent sewage debris from polluting the floor.

MACHINE CONSTRUCTION

Shell roller cleaning machine&Large shell conch cleaning machine&Oyster abalone puree cleaner&automatic Clam cleaner&Seafood decontamination cleaning machine&Shell roller cleaning machine&Large shell conch cleaning machine&Oyster abalone puree cleaner&automatic Clam cleaner&Seafood decontamination cleaning machine&Shell roller cleaning machine&Large shell conch cleaning machine&Oyster abalone puree cleaner&automatic Clam cleaner&Seafood decontamination cleaning machine&Shell roller cleaning machine&Oyster abalone puree cleaner&automatic Clam cleaner&automatic Clam cleaner&automatic Clam cleaner&automatic Clam cleaner

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!