Carrot Washing Machine

Carrot cleaning machine is the use of high pressure spray technology and the role of the brush, the brush texture elasticity is good, effectively avoid manual cleaning of the material damage, the carrot after cleaning to keep intact and clean, by customers all over the welcome and love.

- BJZX

- China

- 20 days

- 100 Sets

- Information

CARROT WASHING MACHINE

FEATURES

The unique design of carrot cleaning machine can be used for carrot cleaning and peeling, food grade material, health and environmental protection, durable, good cleaning effect, simple installation, easy operation, water saving, electricity saving, time saving, clean health, no damage to the product.

Carrot peeling and cleaning machine can be used as Large radish hair removal brush cleaning machine,Automatic wool roller mud cleaning machine,White radish wool roller cleaning machine,Green radish potato brush cleaning machine and so on.

SPECIFICATION

| Model | BJ-HQ |

| Production capacity | 1.5-2.5 T/H |

| Dimensions | 2480×850×850 mm |

| Motor power | 2.2 kw |

Products can be customized, more model parameters please contact me.

RANGE OF CONFIGURATION

Carrot cleaning machine can also clean a variety of rhizomes and hardwood plants, the cleaning effect is good, the machine quality is good, and the collision, friction and scratching phenomenon in manual cleaning is effectively avoided, thus improving the work efficiency.

PRODUCT DETAILED

Carrot washing machines have soft and hard hair two kinds. By replacing different types of brushes, different functions can be achieved.

A soft brush cleans the carrots and removes skin impurities.

The hard brush cleaning machine is suitable for peeling root vegetables.

PRODUCT DESCRIPTION

High pressure sprayer

The device generally hangs from the top of the brush and is connected to a water pipe to supply the stream. Its role is to provide a high-pressure stream of water as the brush rubs the carrot, making the cleaning more thorough.

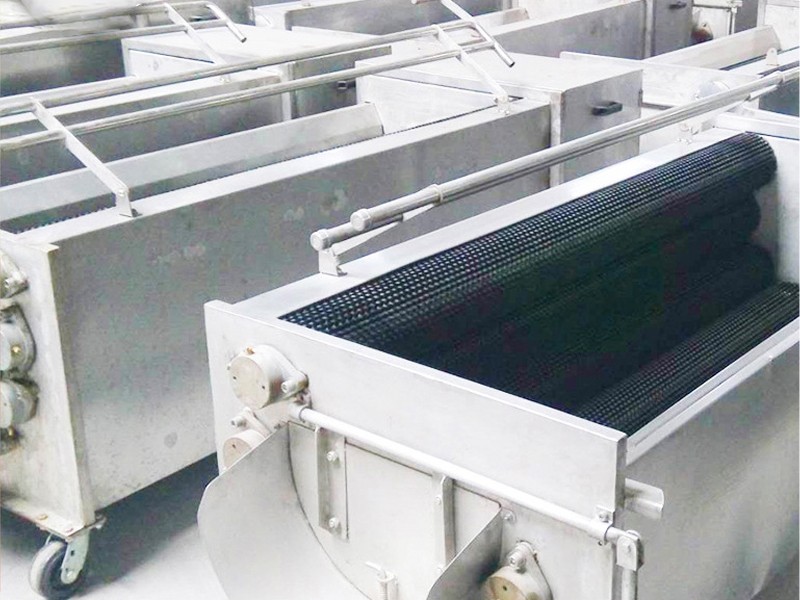

Brush cleaning device

Brush cleaning device is the most important part of brush carrot cleaning machine. The main method is to remove impurities from the surface of the carrot by friction. It is produced by the mutual motion of the brush and the carrot. Since the brush is fully accessible and has access to the bumpy location of the carrot, the machine can clean the carrot more thoroughly.

Frame part

Because the carrot washer is in contact with water for a long time, it is easy to corrosion. Therefore, the frame part of the cleaning machine is mainly made of food-grade 304 stainless steel, which can be in contact with water for a long time without rust, ensuring the service life of the cleaning machine.

Motor part

The motor mainly provides power for the entire operation process of the brush rotation and high pressure injection. The motor part is located on the left side of the machine, hidden under the frame. In order to ensure the smooth operation of the machine, please ensure that the bearing is regularly added with lubricating oil.

MACHINE CONSTRUCTION

Carrot peeling and cleaning machine&Large radish hair removal brush cleaning machine&Automatic wool roller mud cleaning machine&White radish wool roller cleaning machine&Green radish potato brush cleaning machine&Carrot peeling and cleaning machine&Large radish hair removal brush cleaning machine&Automatic wool roller mud cleaning machine&White radish wool roller cleaning machine&Green radish potato brush cleaning machine&Carrot peeling and cleaning machine&Automatic wool roller mud cleaning machine&White radish wool roller cleaning machine&Green radish potato brush cleaning machine&

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!