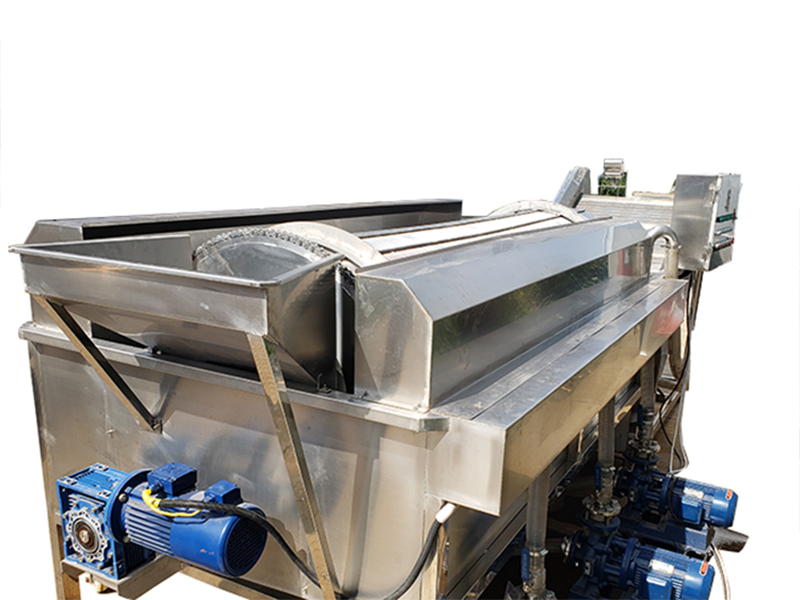

Food drum bubble cleaning machine

Food drum bubble cleaning machine is a new type of cleaning equipment developed by our company, the machine is a drum bubble cleaning machine, the cleaning effect is very good, the cleaning rate exceeds any form of cleaning equipment.

- BJZX

- China

- 20 days

- 100 set

- Information

FOOD DRUM BUBBLE CLEANING MACHINE

FEATURES

Food drum bubble cleaning machine design is reasonable, low water consumption, in line with water-saving requirements, clean, practical, easy operation and maintenance, such as disinfection, the sink can be equipped with a certain concentration of disinfectant.

Stainless steel Vegetable fruit washing machine can be used as Seafood cleaning machine,5000kg/h food cleaning machine,Large fully automated cleaning equipment,Stainless steel washing equipment fruits vegetables and so on.

SPECIFICATION

| Model | BJ-TPX |

| Dimensions | 5000×2000×1500 mm |

| Motor power | 5.25 kw |

Can be customized according to the actual needs of customers.

RANGE OF CONFIGURATION

Kernels of corn

Fresh ginger

Fresh jujube

Food drum bubble cleaning machine is widely used in corn kernels, carrots, ginger, sweet potato, potato, pueraria, cassava, lotus root and other fruits and vegetables cleaning, especially suitable for growing in the soil of fruits and vegetables cleaning, but also widely used in apple, pear, pineapple, dates, prickly pear, strawberry, bayberry, various fruits and vegetables cleaning.

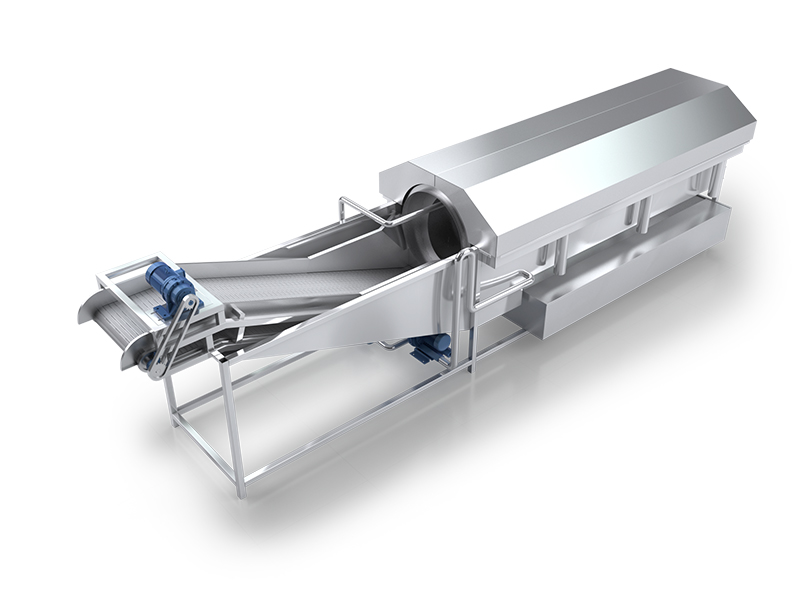

PRODUCT DETAILED

Food drum bubble cleaning machine adopts the principle of bubbling produced by high pressure gas, high pressure spray pipe and countercurrent washing, so that the material is washed by bubbles and sprayed by high pressure water in the whole process of turning and moving, the cleaning effect is good, can effectively remove mud and sand, and the cleaned material is lifted to the next process by the elevator in the cleaning tank.

The water in the tank is filtered through the attached water tank, pressurized by the pipeline pump, and then fed into the tank.

PRODUCT DESCRIPTION

The whole fuselage is made of 304 stainless steel edge treatment, strong structure, practical appearance, good stability, low noise, saving consumables, cleaning water is recycled after filtration, high efficiency, can be completed once cleaning, feeding.

The machine uses high pressure gas to produce bubbling to clean. Effective separation of sediment and impurities on the vegetable.

The amount of high pressure bubbles can be adjusted, which is convenient for customers to flexibly adjust according to the amount of vegetables handled and the degree of cleanliness. It comes with lifting and spraying, the material after rotating drum cleaning is automatically lifted to the designated place, and the spray section adopts an adjustable nozzle to control the water output of the nozzle, which is convenient for customers to flexibly adjust according to different vegetables, effectively protect the skin of fruits and vegetables, and meet the requirements of product export standards.

MACHINE CONSTRUCTION

Stainless steel Vegetable fruit washing machine&Seafood cleaning machine&5000kg/h food cleaning machine&Large fully automated cleaning equipment&Stainless steel washing equipment fruits vegetables&Stainless steel Vegetable fruit washing machine&Seafood cleaning machine&5000kg/h food cleaning machine&Large fully automated cleaning equipment&Stainless steel washing equipment fruits vegetables&Seafood cleaning machine&Seafood cleaning machine&Seafood cleaning machine&5000kg/h food cleaning machine&Large fully automated cleaning equipment&5000kg/h food cleaning machine

COMPANY PROFILE

Through years of growth and development, the company has been equipped with mature technology, stable quality of product manufacturing level, good at innovation management team, the introduction of advanced processing equipment, standardized quality management system, with first-class technology to manufacture high-end equipment in this field, and to achieve professional and fast after-sales service to customers, in the same industry and the market to establish a good brand image.

Our team has supported more than 1,500 food engineering projects at home and abroad, and our products have been exported to dozens of countries and regions including Canada, Mexico, Singapore, Japan, Russia, South Korea, Myanmar, Vietnam and North Korea. With first-class technology to manufacture high-end equipment in this field, and to achieve professional and efficient after-sales service to customers, sincerely hope to cooperate with you, to achieve win-win situation!